What special processes are required for mold development of Convex Shoulder Airless Bottle?

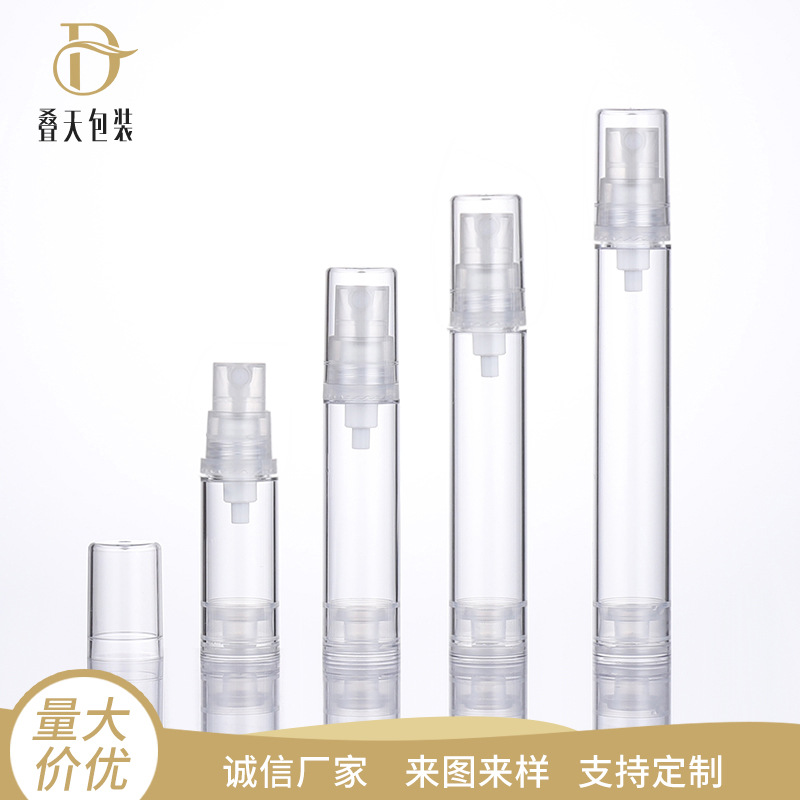

In the field of cosmetic packaging, Convex Shoulder Airless Bottle has gradually become the preferred packaging for high value-added products such as essences and ampoules due to its unique curved shoulder design, sealing performance and high-end texture. However, the mold development of this innovative structure places extremely high demands on the process. As Yuyao Dietian Packaging Co., Ltd., which has been deeply engaged in the manufacture of cosmetic containers for more than ten years, we have summarized the following key process difficulties and solutions through technical precipitation and practical accumulation.

1. Complex curved surface molding: high-precision parting and gas-assisted technology

The curved shoulder design of the convex shoulder vacuum bottle is its core selling point, but this asymmetric curved surface structure is very easy to cause shrinkage or deformation due to uneven cooling during the injection molding process. To this end, mold development requires the use of high-precision five-axis machining technology to ensure that the geometric accuracy of the parting surface is controlled within ±0.02mm. At the same time, through the gas-assisted molding process (Gas-Assisted Molding), high-pressure nitrogen is injected into the mold during the injection molding process, so that the molten plastic evenly fills the bottle shoulder curved surface to avoid structural defects caused by wall thickness differences.

2. Vacuum sealing system: multi-component collaborative design and micro-gap control

The core function of the vacuum bottle depends on the precise matching of the liner and the bottle body. Mold development requires the simultaneous design of the spring return structure and the molding cavity of the piston sealing system, and ensures that the gap tolerance between the components is ≤0.05mm. To this end, we use modular mold design, predict the component shrinkage rate through simulation software, and embed fine-tuning inserts in the mold to achieve "zero running-in" assembly of components after injection molding.

3. Surface treatment process: mirror discharge and nano-coating technology

High-end cosmetic packaging has strict requirements on surface finish. The complex curved surface of the shoulder part needs to be machined by mirror discharge machining (Mirror EDM) to form an ultra-smooth texture of Ra≤0.1μm on the surface of the mold cavity. To further improve scratch resistance, the mold can be integrated with nano-level PVD coating technology, so that the finished bottle has both metallic texture and anti-fingerprint properties.

4. Material adaptability: Rapid cooling solution for high-temperature engineering plastics

To meet the chemical resistance and compressive strength of vacuum bottles, high-transparent engineering plastics such as PMMA and TRITAN are often used. The injection molding temperature of such materials is as high as 280-320°C, which can easily cause thermal deformation of the mold. Our solution is to design a dual-circuit cooling system, embed a spiral copper tube inside the mold, and cooperate with low-temperature water circulation to increase cooling efficiency by 40%, while avoiding stress cracking of the material due to excessive temperature difference.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)