Traditional jar cream vs Airless Cream Bottle: Which packaging can reduce 98% of oxidation waste?

In the skin care industry, consumers often focus on ingredient efficacy, brand reputation and price advantages, but tend to overlook a key factor that directly affects product effectiveness - packaging design. The competition between traditional jar cream and Airless Cream Bottle is essentially an innovation in cosmetic container technology, and it is also the ultimate test of the protection of active ingredients in products. Experimental data show that vacuum pump bottle technology can reduce up to 98% of oxidation waste.

1. The ""invisible killer"" of traditional canning: open oxidation and secondary pollution

Wide-mouth jar cream looks classic and elegant, but it has two fatal flaws:

Irreversible oxidation reaction: Every time the lid is opened for use, the cream comes into direct contact with oxygen and microorganisms in the air, and the active ingredients (such as vitamin C, peptides, and plant extracts) will degrade rapidly. Laboratory data show that the antioxidant efficacy of traditional canned products decreases by an average of 45% after 30 days of opening.

Contamination caused by finger contact: When consumers repeatedly scoop out the cream, bacteria and sebum on their hands will mix into the product, accelerating the growth of microorganisms. A US FDA research report pointed out that the average monthly increase in the total number of colonies in canned skin care products after opening the lid can reach 300%.

2. The ""black technology"" of vacuum pump bottles: How vacuum mechanics lock active ingredients

Airless Cream Bottle achieves revolutionary protection through precise mechanical structure:

One-way isolation system: Using the piston propulsion principle, the product is only output in one direction through the pump head, and the vacuum environment in the bottle completely isolates the air from returning.

Zero residue design: The bottom piston rises synchronously with the amount used to ensure that the contents are 100% residue-free and avoid the ""bottom caking"" problem of traditional cans.

Constant pressure technology: The air pressure balance valve maintains a constant pressure state in the bottle, and the cream can still be output stably even in high altitude or temperature change environments.

Authoritative experimental verification: Under simulated daily use conditions (opening the lid twice a day for 60 days), the peroxide value (POV) of the cream in the vacuum pump bottle is only 2% of that of traditional cans, and the active ingredient retention rate exceeds 95%. This means that every pump of cream actually used by consumers can achieve the original effect when it leaves the factory.

3. Double revolution of environmental protection and commercial value

In addition to technical advantages, vacuum pump bottles are reshaping the industry ecology:

Reducing dependence on preservatives: Due to the isolation of external pollution, the amount of preservatives (such as phenoxyethanol and parabens) added in the formula can be reduced by 50%-70%, which is in line with the global ""clean beauty"" trend.

Extending shelf life: The shelf life of traditional canned products is usually 6-12 months after opening, while vacuum pump bottles can be extended to 18-24 months, reducing channel unsalable losses.

Improving consumer experience: The quantitative pump head accurately controls the single dosage (accurate to 0.02g), which reduces the actual use cost by 30% compared to the random digging of canned products.

4. Yuyao Dietian Packaging: Global Benchmark of Vacuum Packaging Technology

As the promoter of this packaging revolution, *Yuyao Dietian Packaging Co., Ltd. has developed into a full-industry chain manufacturer integrating mold research and development, injection molding, and hot stamping assembly since its establishment in 2011. Its core technical advantages include:

Nano-level sealing process: using medical-grade silicone sealing rings to achieve micron-level airtightness (leakage rate <0.001%).

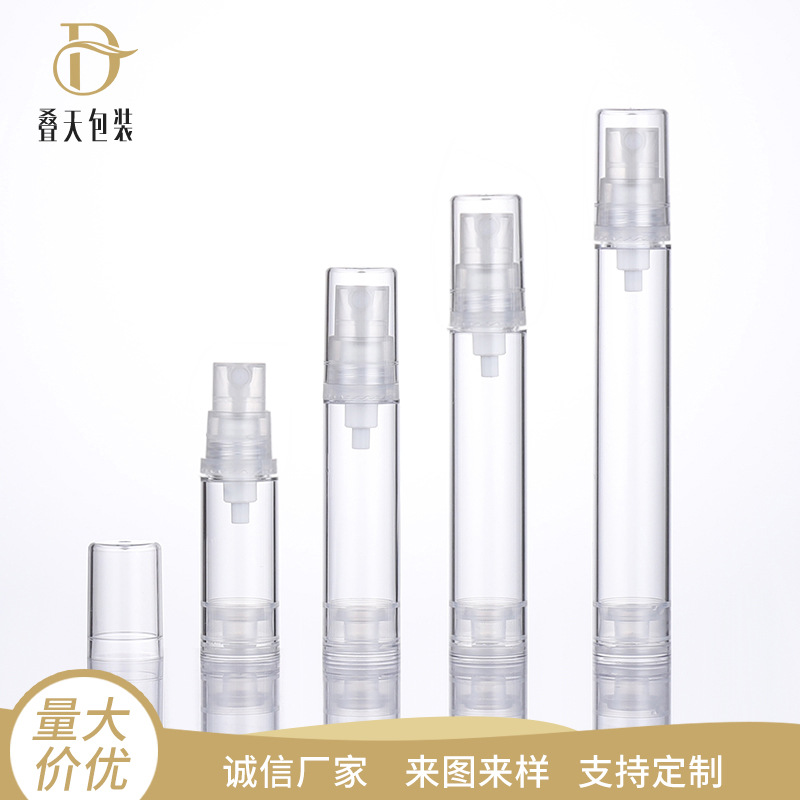

Modular production system: supports flexible customization from 5ml travel packs to 500ml family packs, adapting to multiple categories such as essences, creams, and sunscreens.

Sustainable material solutions: providing environmentally friendly options such as PCR recycled plastics and bio-based polymers, with a carbon footprint 62% lower than traditional packaging.

Currently, the company has an annual production capacity of 30 million cosmetic containers, and its cooperative brands cover more than 20 markets including Europe, America, Asia Pacific, etc., proving the successful leap of vacuum pump bottle technology from laboratory to commercialization.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)