How to Clean and Reuse Your Airless Lotion Bottle Efficiently?

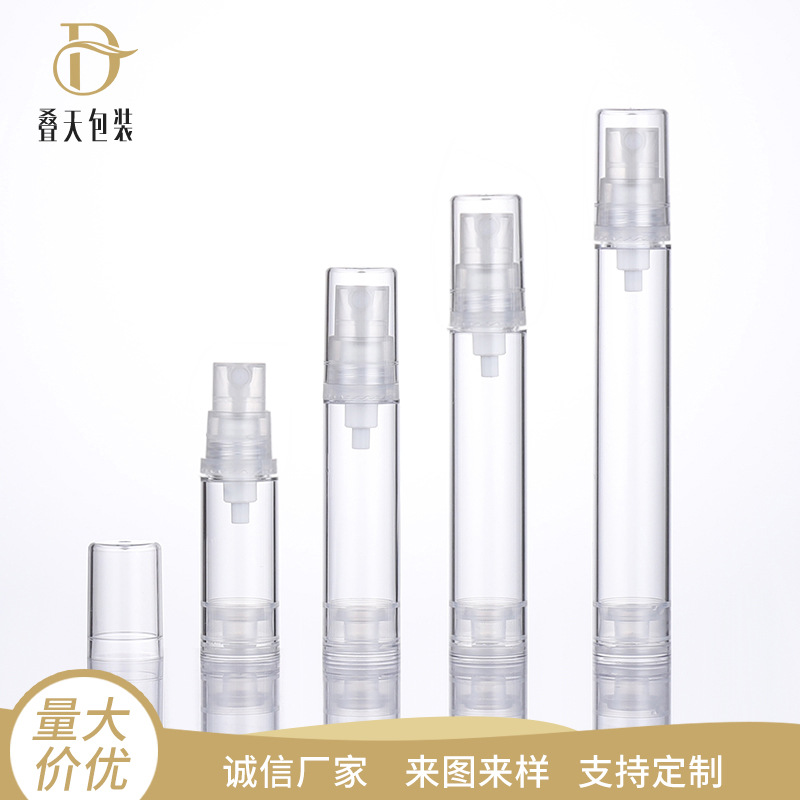

In an era where sustainability and cost-efficiency are paramount, airless lotion bottles have emerged as a game-changer in cosmetic packaging. These innovative containers not only preserve product freshness by preventing air exposure but also minimize waste by dispensing every last drop. However, to maximize their eco-friendly potential, proper cleaning and reuse are essential. As a leader in cosmetic packaging solutions, Yuyao Dietian Packaging Co., Ltd. combines technical expertise with sustainable design to empower users to extend the lifespan of their airless bottles.

Why Reuse Airless Lotion Bottles?

Airless bottles are engineered with a vacuum mechanism that protects contents from contamination and oxidation. Their durable construction—often using materials like PP (polypropylene) or ABS plastic—makes them ideal for repeated use. By reusing these bottles, you:

Reduce plastic waste: The beauty industry generates over 120 billion packaging units annually. Reusing containers directly combats landfill pollution.

Save money: High-quality bottles can last years with proper care, eliminating the need for frequent replacements.

Maintain product integrity: Airless designs prevent bacterial growth, ensuring safe reuse for serums, creams, or DIY formulations.

Step-by-Step Cleaning Process

Follow these professional techniques to clean your airless lotion bottle thoroughly:

1. Disassemble the Bottle

Most airless bottles consist of a pump, a piston, a bottle body, and a cap. Gently twist off the pump mechanism and remove the piston (if applicable). Check the manufacturer’s guidelines—Yuyao Dietian’s bottles, for example, are designed for easy disassembly without tools.

2. Rinse with Warm Water

Flush the bottle and components under lukewarm water to remove residual product. Avoid boiling water, as extreme heat may warp plastic parts. For stubborn residues, soak the parts in a mild soap solution for 10–15 minutes.

3. Deep Clean with a Brush

Use a soft-bristled brush (e.g., a baby bottle brush) to scrub the interior walls and piston chamber. Focus on crevices where product buildup occurs. Pro tip: For oily residues, a diluted vinegar solution (1:3 ratio with water) effectively breaks down lipids without damaging the plastic.

4. Sanitize for Safety

To eliminate bacteria, sanitize components with 70% isopropyl alcohol or a UV sterilization device. Avoid harsh chemicals like bleach, which can degrade plastic over time.

5. Dry Thoroughly

Air-dry all parts upside-down on a clean towel in a well-ventilated area. Ensure no moisture remains, as damp environments promote mold growth.

6. Reassemble and Test

Once dry, reassemble the bottle and pump. Press the pump several times to reset the vacuum mechanism before refilling.

Maximizing Longevity: Best Practices

Label clearly: Use waterproof labels to track refill dates and contents.

Avoid incompatible products: Refill with formulas of similar viscosity to prevent pump clogging.

Store properly: Keep bottles in a cool, dry place away from direct sunlight to prevent material degradation.

Why Choose Professional-Grade Airless Bottles?

Not all airless bottles are created equal. Cheaply made containers may leak, break, or fail to maintain a vacuum after cleaning. Yuyao Dietian Packaging Co., Ltd., a trusted manufacturer since 2011, specializes in precision-engineered airless bottles designed for durability and repeated use. With ISO-certified production facilities and 30 million units manufactured annually, their containers undergo rigorous testing for leak resistance, chemical stability, and mechanical endurance.

By investing in high-quality packaging like Yuyao Dietian’s airless bottles, you ensure seamless functionality across hundreds of uses while aligning with global sustainability goals.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)