Why Are Airless Spray Bottles Revolutionizing Cosmetic Packaging?

In an era where sustainability, efficacy, and consumer experience dominate the beauty industry, airless spray bottles have emerged as a groundbreaking innovation in cosmetic packaging. Combining advanced engineering with user-centric design, these containers are redefining how brands deliver skincare and beauty products. For manufacturers like Yuyao Dietian Packaging Co., Ltd.—a leader in cosmetic container solutions since 2011—airless technology represents not just a trend but a transformative shift in packaging standards.

1. Preserving Product Integrity: A Scientific Breakthrough

Traditional pump bottles and jars expose formulations to air, light, and contaminants, accelerating oxidation and microbial growth. This compromises active ingredients like vitamins, peptides, and antioxidants, reducing product efficacy over time. Airless spray bottles, however, utilize a vacuum-sealed mechanism that creates a hermetic barrier. As the product is dispensed, a piston rises to prevent air from entering, ensuring 100% product protection.

For brands formulating with sensitive or high-value ingredients—think serums, sunscreens, or anti-aging creams—airless packaging is a game-changer. Independent studies show that airless systems extend shelf life by up to 30% compared to conventional packaging, safeguarding both quality and brand reputation.

2. Eliminating Waste: Precision Meets Sustainability

One of the most compelling advantages of airless spray bottles is their ability to minimize product waste. Traditional containers often leave 20–25% of formulations trapped in corners or unreachable by pumps, as highlighted by Harvard University’s packaging research. Airless technology, with its collapsible design, ensures near-total evacuation, achieving 97–99% product utilization. This efficiency aligns with the growing consumer demand for sustainable solutions, reducing landfill waste and maximizing value.

Moreover, Yuyao Dietian’s airless bottles are designed with eco-conscious materials, including recyclable plastics and PCR (post-consumer recycled) resins, meeting global regulatory standards like the EU’s Circular Economy Action Plan. For brands committed to sustainability, this innovation bridges ecological responsibility with commercial viability.

3. Enhancing User Experience: Luxury and Hygiene Combined

Airless spray bottles elevate the tactile and functional aspects of skincare routines. The smooth, controlled misting mechanism ensures even distribution for lightweight textures like toners, essences, or facial mists. Unlike aerosol sprays, which rely on propellants, airless systems operate via mechanical pressure, making them safer for delicate facial skin and the environment.

Hygiene is another critical factor. By preventing finger-to-product contact—a common issue with jars—airless packaging eliminates cross-contamination risks. This feature resonates deeply in a post-pandemic market, where 68% of consumers prioritize hygienic packaging (Mintel, 2023). Yuyao Dietian further enhances usability with ergonomic designs, anti-slip grips, and customizable spray patterns tailored to product viscosity.

4. Driving Brand Differentiation: The Aesthetics of Innovation

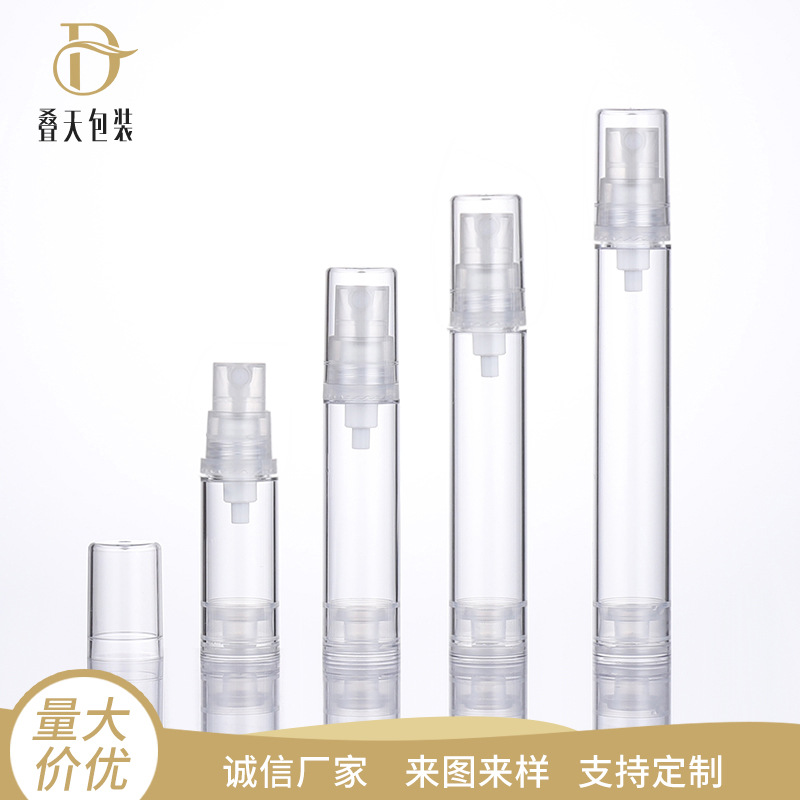

In a crowded beauty market, packaging is a silent ambassador for brand identity. Airless spray bottles offer a sleek, modern aesthetic that communicates premium quality and technological sophistication. Yuyao Dietian leverages advanced techniques like hot-stamping printing and metallic finishes to create visually striking designs that stand out on shelves. Customizable shapes, colors, and spray nozzles allow brands to align packaging with their unique storytelling—whether minimalist, futuristic, or eco-friendly.

For indie brands competing against established players, airless technology provides a cost-effective way to signal innovation. Meanwhile, luxury labels can reinforce exclusivity through bespoke designs and patented mechanisms.

Yuyao Dietian Packaging: Pioneering the Future of Airless Solutions

As a vertically integrated manufacturer with over a decade of expertise, Yuyao Dietian Packaging Co., Ltd. has positioned itself at the forefront of airless packaging innovation. From mold development to injection molding and assembly, the company’s end-to-end capabilities ensure stringent quality control and rapid scalability. Its annual production capacity of 30 million units serves global clients seeking reliable, high-performance containers.

By investing in R&D and eco-friendly materials, Yuyao Dietian addresses both market demands and regulatory shifts. Its airless spray bottles are not just containers but strategic tools for brands aiming to lead in efficacy, sustainability, and consumer loyalty.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)