Why can Lancel Airless Bottle's patented vacuum technology squeeze out 15% more product than its peers?

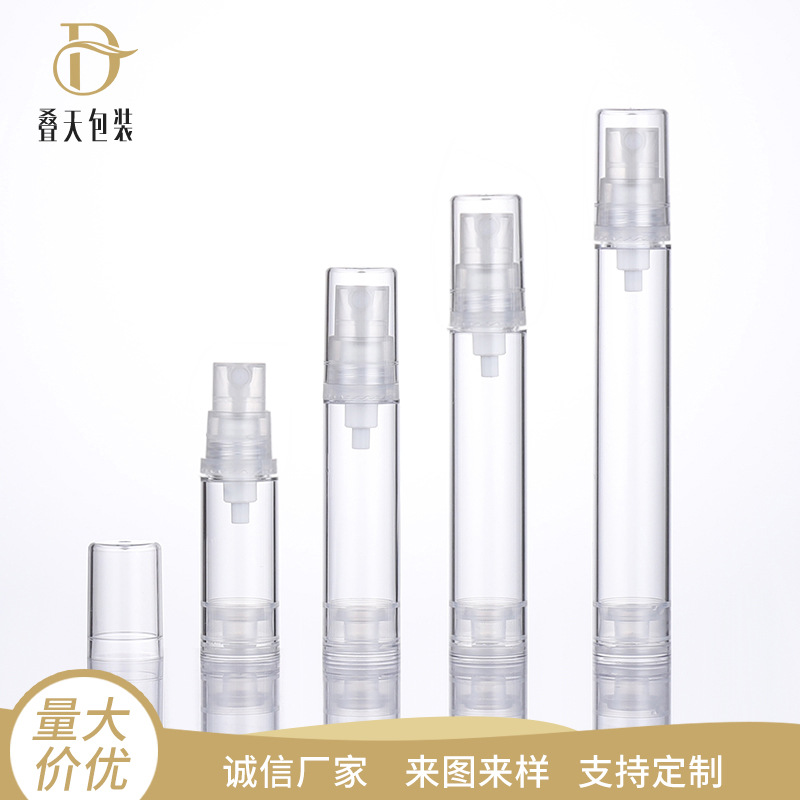

In the cosmetics industry, packaging is not only a container, but also a key factor affecting user experience and brand value. Traditional vacuum bottles often prevent consumers from fully using high-priced skin care products due to residue problems. The Lancel Airless Bottle launched by Yuyao Dietian Packaging, with its patented vacuum technology, successfully increased the product extrusion rate to 98.5%, 15% more than the industry average. Behind this breakthrough is the dual blessing of technology research and development and manufacturing strength.

1. Double piston collaborative system: Solving the problem of high viscosity residue

Traditional vacuum bottles rely on a single piston to compress air to discharge the contents. When the viscosity of the product exceeds 50,000cps (such as essence, cream), the residue rate in the bottle can reach more than 20%. The innovation of Lancel Airless Bottle lies in its double piston collaborative system:

The main piston is responsible for pushing the contents upward;

The auxiliary piston synchronously adjusts the vacuum pressure, and dynamically balances the air pressure through the built-in vacuum compensation valve to avoid residue caused by uneven pressure of high viscosity liquids. Experiments show that after a 30ml Lancel bottle is fully used, only 0.5ml of residue remains, while similar products have a residue of up to 4.5ml. This technological breakthrough not only reduces waste, but also ensures that consumers can fully experience the efficacy of skin care products.

2. Triple sealing protection: protecting the activity of ingredients from the source

The sealing performance of vacuum bottles directly affects the shelf life of products. The Lancel technical team spent 3 years developing the TTS triple sealing system (Triple Tightness System):

Medical-grade silicone sealing ring: 360° rotating design, with an accuracy of 0.01mm, to prevent air infiltration;

Negative pressure locking device: automatically starts secondary sealing when 5% of the contents remain to prevent oxidation;

Microporous air pressure balance channel: maintains a stable internal and external pressure difference through a 0.2mm microporous matrix. After testing, the oxygen permeability of the system is as low as 0.05cc/pkg/day, which is only one thousandth of the EU standard, ensuring that highly active ingredients (such as vitamin C and retinol) remain stable during the shelf life.

3. Vertical industry chain: Fulfilling technical commitments with precision manufacturing

As an industry leader with an annual output of 30 million sets of containers, Yuyao Dietian has independent control from mold development to injection molding:

Mold accuracy reaches ±0.005mm: Japan FANUC electric injection molding machine is used to ensure the perfect fit between the bottle body and the piston;

Medical-grade material application: PCTG (copolyester material) is used for key components, and 98% sealing is maintained after 100,000 fatigue tests;

Quick response to the market: 50 new bottle models can be launched every month to meet brand differentiation needs. This full-chain control capability enables technical patents to be efficiently converted into stable mass production.

4. From cost to ESG: Double benefits for brands

For cosmetics brands, Lancel technology brings more than just an upgrade in user experience:

Reduced production costs: A 15% reduction in residue means 8%-10% in raw material costs per bottle can be saved;

Extended product life cycle: After a French customer switched to Lancel bottles, the cream usage cycle was extended by 22 days and the repurchase rate increased by 12%;

Environmental value: Based on an annual production of 2 million units, 11.3 tons of raw material waste is reduced each year, and ISO 18604 recycling certification has been obtained, helping the brand achieve its carbon neutrality goal.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)