Why Is PP Material the Ideal Choice for Airless Lotion Bottles in Sustainable Packaging?

In an era where environmental responsibility is no longer optional but imperative, the beauty and skincare industry faces mounting pressure to adopt sustainable packaging solutions. Among the myriad of materials available, polypropylene (PP) has emerged as a frontrunner for airless lotion bottles, striking an optimal balance between functionality, durability, and eco-friendliness. As a leader in cosmetic container manufacturing, Yuyao Dietian Packaging Co., Ltd. leverages PP’s unique properties to deliver packaging that aligns with global sustainability goals without compromising performance. Let’s explore why PP is revolutionizing airless bottle design.

1. Superior Recyclability: Closing the Loop on Plastic Waste

Polypropylene is a thermoplastic polymer renowned for its high recyclability. Unlike mixed-material packaging that clogs recycling streams, PP can be efficiently processed and repurposed into new products, reducing reliance on virgin plastics. According to the Association of Plastic Recyclers, PP recycling rates have surged by 25% since 2020, driven by advancements in sorting technologies and circular economy initiatives. Yuyao Dietian Packaging prioritizes PP to support closed-loop systems, ensuring that airless bottles can be transformed into future packaging or industrial applications, thereby minimizing landfill waste.

2. Durability Meets Lightweight Design

Airless lotion bottles require materials that withstand rigorous conditions—from production lines to daily consumer use. PP excels here: its high resistance to chemicals, moisture, and physical stress ensures product integrity while preventing oxidation and contamination. Additionally, PP’s lightweight nature reduces transportation-related carbon emissions. For instance, replacing traditional glass with PP cuts packaging weight by up to 80%, slashing fuel consumption and greenhouse gas emissions across supply chains—a critical advantage for brands targeting carbon neutrality.

3. Compatibility with Sustainable Additives

Modern PP formulations can integrate post-consumer recycled (PCR) content or bio-based alternatives without sacrificing performance. Yuyao Dietian Packaging employs advanced injection molding techniques to incorporate up to 30% PCR-PP into airless bottles, aligning with EU and U.S. regulatory standards for recycled content. Furthermore, PP’s compatibility with additives like mineral fillers enhances biodegradability in specific environments, offering flexibility for brands navigating diverse sustainability frameworks.

4. Airless Technology Synergy

The airless pump mechanism, which preserves sensitive formulations by eliminating backflow and air exposure, demands precision engineering. PP’s dimensional stability and moldability make it ideal for creating airtight seals and complex geometries. Yuyao Dietian’s expertise in mold development ensures that PP airless bottles maintain consistent dispensing accuracy, extending product shelf life and reducing waste from spoiled cosmetics—a win for both consumers and the planet.

5. Cost-Effectiveness for Scalable Sustainability

Transitioning to sustainable materials often raises cost concerns, but PP offers an economical solution. Its low melting point reduces energy consumption during production, while its durability lowers replacement costs for consumers. By optimizing manufacturing processes, Yuyao Dietian delivers high-volume outputs—30 million containers annually—at competitive prices, proving that eco-conscious packaging need not come at a premium.

Yuyao Dietian Packaging: Pioneering PP Innovation

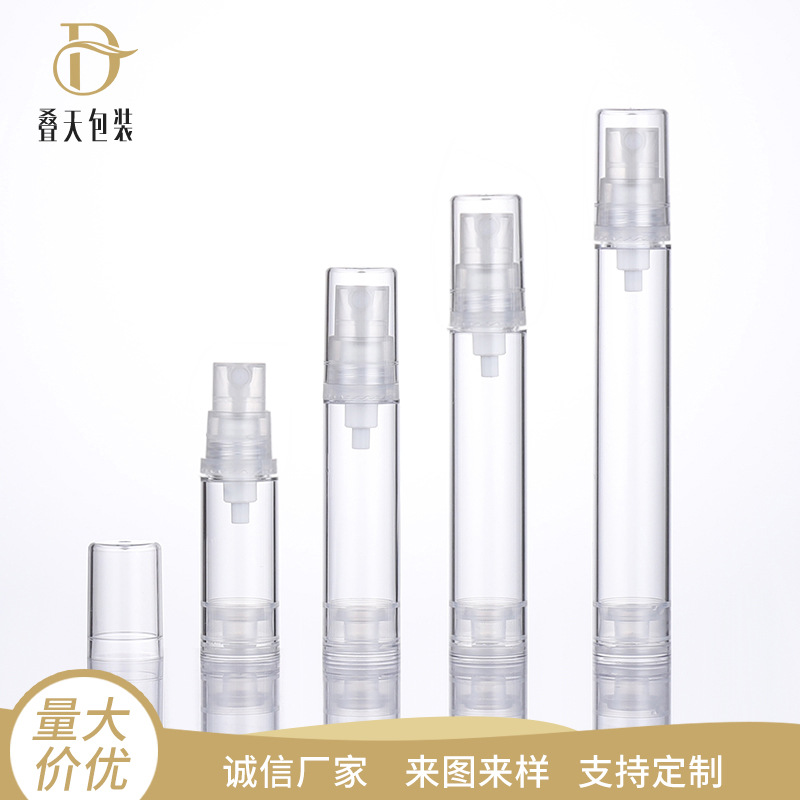

Since its founding in 2011, Yuyao Dietian Packaging Co., Ltd. has specialized in crafting premium cosmetic containers, combining mold development, injection molding, and assembly under one roof. With a annual production capacity of 30 million units, the company serves global brands seeking reliable, sustainable PP Airless Lotion Bottle. By prioritizing PP, Yuyao Dietian not only meets stringent FDA, REACH, and ISO certifications but also empowers clients to achieve ESG targets through smarter material choices.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg?imageView2/2/w/1000/h/1000/format/webp/q/100)

.jpg)