Can Rotary Airless Bottles Reduce Product Waste Compared to Traditional Pumps?

In the competitive landscape of cosmetic packaging, innovation is not just about aesthetics—it’s about functionality, sustainability, and cost efficiency. One critical question facing brands today is whether advanced packaging solutions like rotary airless bottles can outperform traditional pump systems in reducing product waste. As a leader in cosmetic container manufacturing, Yuyao Dietian Packaging Co., Ltd. leverages its decade-long expertise to address this debate with scientific insights and real-world applications.

The Hidden Cost of Traditional Pump Systems

Traditional pump dispensers have long been the default choice for liquid and semi-liquid cosmetics, such as serums, lotions, and creams. However, these systems suffer from inherent design flaws that contribute to product waste:

Residual Product Trapped in Packaging: Up to 20–25% of viscous formulations remain stuck in pump tubes or bottle walls, inaccessible to users.

Oxidation and Contamination: Repeated exposure to air accelerates ingredient degradation and increases microbial growth risks.

Overdispensing: Manual pumps lack precision, often releasing more product than needed per use.

These limitations not only frustrate consumers but also inflate costs for brands by forcing overformulation to compensate for wasted product.

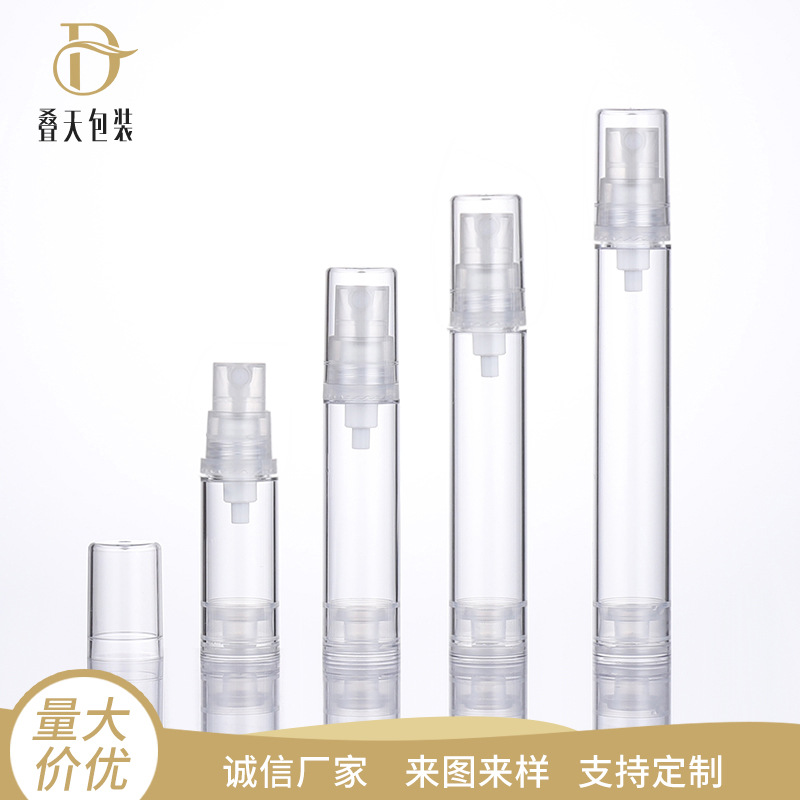

Rotary Airless Bottles: A Precision-Driven Alternative

Rotary airless bottles, pioneered by innovators like Yuyao Dietian Packaging Co., Ltd., utilize a vacuum-sealed mechanism to address these challenges. Here’s how they work:

Vacuum-Driven Dispensing: A piston at the bottle’s base rises as the product is dispensed, maintaining a constant vacuum that eliminates air contact.

Rotary Activation: A twistable cap controls the dispensing aperture, allowing users to release precise amounts of product (as low as 0.1 mL per rotation).

100% Evacuation: The piston ensures near-total evacuation, leaving less than 2% residue—even for high-viscosity creams.

Scientific Advantages in Waste Reduction

Independent studies and Yuyao Dietian’s internal testing validate the superiority of airless technology:

Extended Shelf Life: By preventing oxidation, airless bottles preserve active ingredients 30–50% longer than pump systems.

Minimal Residual Waste: Less than 2% product remains in airless containers versus 15–25% in traditional pumps.

Dosing Accuracy: Controlled dispensing reduces overuse by 40%, as shown in consumer trials.

For a brand producing 1 million units annually, switching to rotary airless bottles could save over 20 tons of product from being wasted—a significant cost and sustainability win.

Yuyao Dietian’s Engineering Expertise

Since its founding in 2011, Yuyao Dietian Packaging Co., Ltd. has emerged as a pioneer in airless packaging innovation. The company’s vertically integrated capabilities—from mold development to assembly—enable tailored solutions:

Patented Piston Designs: Engineered for smooth, consistent dispensing across viscosities.

Modular Components: Interchangeable caps and collars allow compatibility with existing production lines.

Sustainability Focus: Recyclable materials and reduced material thickness (achieved via precision molding) lower carbon footprints.

With a production capacity of 30 million units annually, Yuyao Dietian supports global brands in transitioning to waste-minimizing packaging without compromising scalability.

English

English 中文简体

中文简体 Español

Español عربى

عربى

.jpg)